Solutions

-

- Drilling Tools T38 3660Mm MM

Drilling Tools T38 3660Mm MM MF Thread...

-

- Hex22 Pneumatic Rock Drilling Tool

Small Hole Drillig Tools Hex22 7/11/12 Degrees Tools Taper Drill Rod...

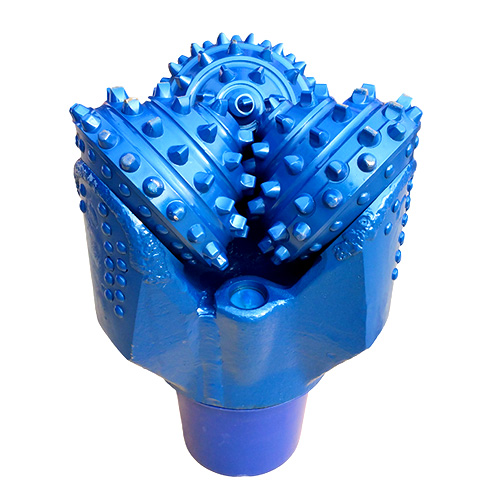

Tricone Drilling Bits-TCI

Tricone Drilling Bits with Tungsten Carbide Inserts (TCI): An Overview

- Structure and Design:

Three Cones: Tricone bits feature three rotating cones (typically mounted on bearings), which work together to crush and chip rock formations. The cones rotate as the drill string turns, enabling efficient rock penetration.

Tungsten Carbide Inserts (TCI): Instead of steel teeth, TCI bits use inserts made of tungsten carbide—a ultra-hard, wear-resistant material. These inserts are arranged in rows on the cones, with shapes and sizes tailored to specific formations (e.g., chisel, conical, or wedge-shaped inserts).

Bearings: Modern TCI bits often use sealed, lubricated roller bearings to extend bearing life in harsh conditions.

Nozzles: Interchangeable nozzles direct drilling fluid (mud) to cool the bit, remove cuttings, and prevent balling.

- Working Principle:

The cones rotate and roll across the formation, with TCI inserts applying compressive and shear forces to fracture rock through a combination of crushing, grinding, and chipping.

– The bit’s “journal angle” (angle of cone axes relative to the borehole) influences aggressiveness; steeper angles suit harder formations.

- Applications:

Formations: Ideal for medium to hard, abrasive formations (e.g., shale, limestone, sandstone). Less effective in soft, non-abrasive formations where steel-tooth bits or PDC bits excel.

Industries: Widely used in oil/gas drilling, mining, water well drilling, and geothermal projects.

Directional Drilling: TCI bits handle doglegs and side forces better than some PDC bits due to their rolling action.

- Advantages:

Durability: Tungsten carbide resists abrasion and heat, extending bit life in hard formations.

Versatility: Customizable insert layouts and nozzle configurations adapt to varying rock types.

Cost-Effectiveness: Refurbishable (inserts and bearings can be replaced), reducing long-term costs.

Stability: Tricone design minimizes vibration in heterogeneous formations.

- Limitations:

ROP in Soft Formations: Lower rate of penetration (ROP) compared to steel-tooth or PDC bits in soft formations.

Bearing Wear: Bearings may fail before inserts wear out, especially in high-RPM applications.

Cost: Higher initial cost than steel-tooth bits, though often justified by longevity in hard rock.

- Comparison to Other Bit Types:

Steel-Tooth Bits: Better for soft formations but wear faster in abrasive/hard rock.

PDC Bits: Use shearing action for faster ROP in soft to medium formations but struggle in highly abrasive or interbedded layers.

- Selection Considerations:

Formation Hardness: Use TCI bits for medium-hard to hard, abrasive formations.

Drilling Parameters: Optimize weight on bit (WOB) and RPM to balance ROP and bit life.

Hydraulics: Ensure adequate mud flow to cool inserts and clear cuttings.

Directional Needs: Suitable for directional drilling where stability is critical.

- Maintenance Tips:

Inspect inserts for breakage and cones for bearing wear post-run.

Clean nozzles to prevent clogging.

Avoid dropping or mishandling to protect inserts from premature damage.

Conclusion:

TCI tricone bits are a robust solution for challenging drilling environments, offering a balance of durability and adaptability. Their design makes them indispensable in hard, abrasive formations, though proper selection and maintenance are key to maximizing performance.

Inquiry

Here you can submit any questions and we will get back to you as soon as possible. We will not disclose the information you submit to anyone, please rest assured.

Inquiry