Solutions

-

- Drilling Tools T38 3660Mm MM

Drilling Tools T38 3660Mm MM MF Thread...

-

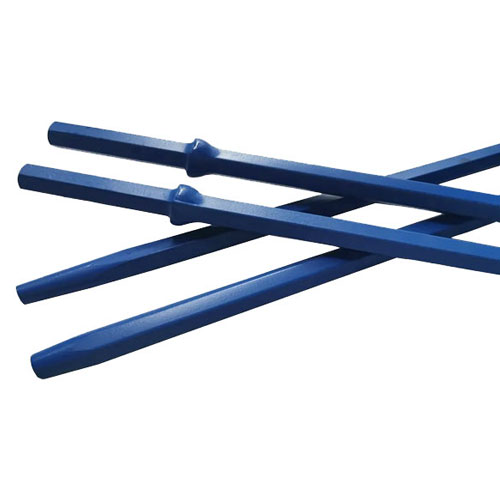

- Hex22 Pneumatic Rock Drilling Tool

Small Hole Drillig Tools Hex22 7/11/12 Degrees Tools Taper Drill Rod...

Choosing Drill Steel and Rock Drill Bits

When selecting drill steel and rock drill bits, multiple factors need to be considered comprehensively to ensure that the selected product can meet specific drilling requirements and provide the best performance and durability. Here are some key selection points:

Firstly, understanding the specific requirements of drilling projects is crucial. This includes factors such as drilling depth, rock hardness, expected drilling speed, and budget. Different drilling steel and drill bit designs are suitable for different rock types and drilling conditions. For example, for rocks with higher hardness, it may be necessary to choose drill bits and drill steel with higher hardness and wear resistance.

Secondly, the quality and durability of drilling steel are also important factors to consider. High quality drilling steel should have sufficient strength and toughness to withstand the impact and vibration during the drilling process. In addition, the diameter and length of the drilling steel should also be matched with the drill bit and drilling equipment used to ensure the stability and efficiency of the drilling process.

When choosing a rock drill bit, in addition to considering its material (such as hard alloy, steel, or diamond) and hardness, it is also necessary to pay attention to the shape and size of the drill bit. Different drill bit shapes (such as pointed, flat, or concave) and sizes are suitable for different drilling needs. For example, pointed drills may be more suitable for penetrating harder rocks, while flat or concave drills may be more suitable for creating smooth holes in specific types of rocks.

In addition, it is necessary to consider the compatibility between the drill bit and the drilling steel. Ensure smooth coordination between the selected drill bit and drilling steel to improve drilling efficiency and reduce failure rates. This may require reference to the manufacturer’s recommendations or consultation with professionals.

Finally, cost is also an important factor to consider when choosing steel and rock drill bits. Finding the most cost-effective product within budget is crucial. At the same time, it is also important to avoid overly pursuing low prices while neglecting product quality and performance.

In summary, when selecting steel and rock drill bits, it is necessary to comprehensively consider multiple factors such as project requirements, product quality, drill bit shape and size, compatibility, and cost. By carefully evaluating and comparing different products, the most suitable drilling steel and rock bits for a specific drilling project can be selected.

Inquiry

Here you can submit any questions and we will get back to you as soon as possible. We will not disclose the information you submit to anyone, please rest assured.

Inquiry