Solutions

-

- Drilling Tools T38 3660Mm MM

Drilling Tools T38 3660Mm MM MF Thread...

-

- Hex22 Pneumatic Rock Drilling Tool

Small Hole Drillig Tools Hex22 7/11/12 Degrees Tools Taper Drill Rod...

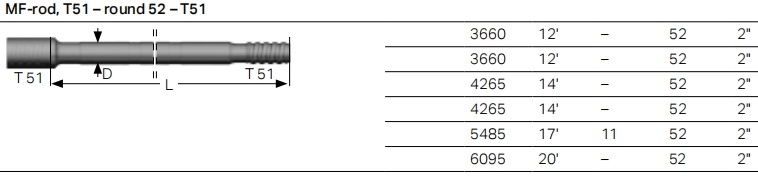

Shandike MF-rod T51–round 52–T51

Date: 2024-10-22 From: SDK Author: admin

T51 MF rod represents a distinct specification and type of drill rod, predominantly utilized in rock drilling activities across mining, construction, and various other industries. Below is a comprehensive elaboration on T51 MF rod:

1. Specification and Type

- T51: This denotes the threading specification for drill rods. Here, “T” stands for Threaded, while “51” signifies a particular size or model. Drill rods adhering to the T51 specification are engineered to exhibit high strength and precision, essential for enduring the rigorous demands and complex conditions of rock drilling operations.

- MF: This could signify the manufacturer’s branding, specific technical attributes, or a product series. It may also indicate unique design elements or performance capabilities, such as rapid connectivity, robust strength, or exceptional wear resistance.

2. Design Characteristics

- High Strength: T51 MF rods are crafted from premium alloy steel, stainless steel, or other high-strength materials, ensuring resilience against substantial torques and axial forces.

- High Precision: The threaded sections undergo meticulous machining to guarantee a secure fit with drilling machinery, preventing loosening or detachment during use.

- Quick Connection: The MF designation may imply a quick-connect feature, facilitating swift rod replacements and enhancing operational efficiency.

- Wear Resistance: Given the challenging nature of rock drilling environments, the threaded portions of T51 MF rods often undergo specialized treatments to bolster their wear resistance and prolong service life.

3. Application Domains

T51 MF rods find extensive application in rock drilling tasks across mining, stone quarrying, construction, and other sectors. By connecting rods of varying lengths, they can accommodate drilling requirements at different depths. Furthermore, they can seamlessly integrate with other rock drilling tools and equipment, fostering more efficient drilling operations.

Extension and Tunneling Rods (Including MM Rod and Male/Female [M/F] Rod, Speed Rod)

- Thread Sizes: Encompassing R22, R25, R28, R32, R35, R38, T38, T45, and T51.

- Rod Diameters: Available in round diameters of 32mm, 39mm, 46mm, and 52mm, as well as hexagonal diameters of 22mm, 25mm, 28mm, 32mm, and 35mm.

- Effective Lengths: Range from 600mm to 6,400mm for extension rods and 915mm to 6,100mm for male/female and speed rods.

Drifting and Tunneling Rods

- Thread Sizes: Including R22, R25, R28, R32, R38, and T38.

- Rod Diameters: Offered in round diameters of 32mm and 39mm, as well as hexagonal diameters of 25mm, 28mm, 32mm, and 35mm.

- Effective Lengths: Span from 2,100mm to 6,400mm.

These rods cater to the diverse needs of drifting and tunneling projects, ensuring reliability and efficiency in challenging drilling scenarios.