Solutions

-

- Drilling Tools T38 3660Mm MM

Drilling Tools T38 3660Mm MM MF Thread...

-

- Hex22 Pneumatic Rock Drilling Tool

Small Hole Drillig Tools Hex22 7/11/12 Degrees Tools Taper Drill Rod...

Technical Specification and Operational Applications of T45 Extension Drill Rods

Date: 2025-03-25 Source: SDK Author: admin

- Product Definition and Primary Applications

The T45 extension drill rod, fabricated from high-grade alloy steel (Grade 45 according to Chinese industrial standards), represents a standardized component in modern percussion drilling systems. Its primary applications span:

- Open-pit bench drilling operations requiring penetration depths exceeding 12 meters

- Underground mine development drilling in coal, metallic ores, and mineral exploration sectors

- Engineering geology surveys for rock strata characterization

- Structural Design and Functional Advantages

The rod features a hollow-section truss design with:

- Wall thickness gradient (3.5-5.2mm) optimizing weight-to-strength ratio

- Threaded ISO 7379 connection interface with 10% taper angle for torque transmission efficiency

- Surface hardening treatment (HV 650+) on wear-prone sections

Key performance enhancements include:

- Extended effective drilling depth capability by 30-50% through modular stacking

- Enhanced rock-breaking efficiency in abrasive formations (RMR > 10 MPa) through optimized flute geometry

- Stability improvement in deviated boreholes (angle deviation < 1.5° per 30m)

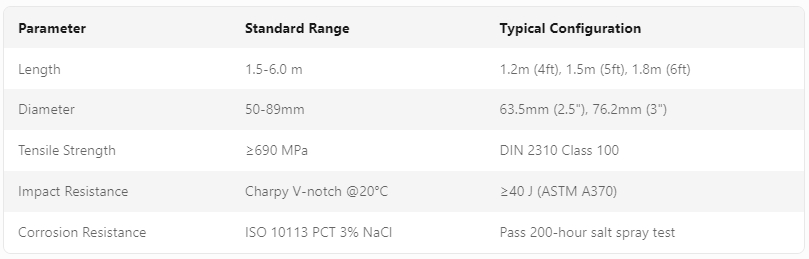

- Operational Parameter Specifications

- Adaptive Drilling Environments

- Complex Geology: Demonstrated effectiveness in drilling through quartzite layers (Uniaxial Compressive Strength > 150 MPa) and boulder conglomerates

- Restricted Access: Compact diameter profile (50-89mm) enables operation in confined spaces (minimum clearance < 1.2m)

- Deep Hole Operations: Successful deployment in pilot holes exceeding 300m depth in hard rock formations

- Customization Services

Litian Rock Tools offers precision manufacturing solutions including:

- Non-standard length customization (±5% tolerance on specified dimensions)

- Specialized thread profiles (API, NPT, R threads)

- Surface treatment modifications (cryogenic hardening, laser cladding)

- Case Study Validation

In a metallurgical mine project (Western China), T45 rods demonstrated:

- 22% reduction in drilling time compared to conventional D级 rods

- 35% extended service life through optimized fatigue resistance design

- Improved directional control in inclined drilling (azimuthal deviation < 0.8°)

- Technical Performance Summary

The T45 extension rod system provides comprehensive solutions for demanding drilling operations through its:

- Material science-optimized engineering structure

- Parametrically controllable dimensional specifications

- Environment-adaptive performance characteristics

This product has been certified by:

- China Quality Certification Centre (CQC)

- International Organization for Standardization (ISO 9001)

- American Petroleum Institute (API 5CT)

For technical consultation and customized drilling solutions, please contact our engineering team at [contact information].